In the area of construction, fiber mesh concrete stands out as a revolutionary approach, marrying strength with durability.

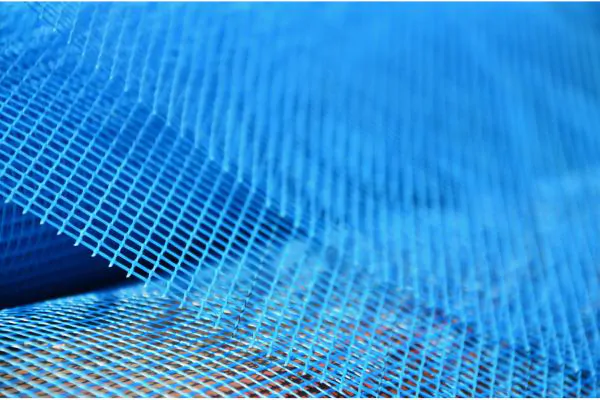

This composite material embeds tiny fibers into the concrete mix, paving the way for structures that not only defy the test of time but also challenge traditional construction methodologies.

The shift from conventional reinforcement methods, such as wire mesh, to avant-garde fiber mesh for concrete brings a new perspective on resilience and performance.

Offering insights into this transformative material, the discussion ahead unveils the intricacies of fiber mesh concrete, its advantages, and how it compares to older methods like wire mesh.

Keep reading to unravel the full potential of concrete fiber mesh in modern-day construction.

What is Fiber Mesh Concrete?

Fiber mesh concrete emerges as a fundamental ingredient in modern construction, offering enhanced strength and durability.

This material integrates finely dispersed fibers, typically made from steel, glass, or synthetic compounds, into concrete mixtures, aiming to mitigate the material’s inherent brittleness and improve its performance under stress.

Ideal for a myriad of construction projects, from industrial flooring to residential driveways, its application hinges on the demands for resistance against cracks and longevity.

The following sections will delve into the nature and makeup of fiber mesh for concrete and outline scenarios signaling its optimal use in construction endeavors.

Definition and composition

Fiber mesh concrete incorporates a plethora of finely divided fibers, which can vary from steel and glass to synthetic materials, uniformly mixed into concrete to create a composite material. This blend significantly enhances the concrete’s integrity, resulting in an increased ability to withstand various loading conditions and impacts without succumbing to the common failings of traditional concrete, such as cracking and spalling. At its core, this innovative composition marks a pivotal advancement in construction materials, showcasing a remarkable balance between strength and flexibility.

When to use it in construction projects

Identifying when to use wire mesh in concrete is pivotal in leveraging its benefits for construction projects. Its utilization is particularly advantageous in areas subjected to heavy loads and high traffic, such as industrial flooring, highways, and airport runways, where the resilience and longevity of the material are critical for maintaining structural integrity. Additionally, residential applications, including driveways, patios, and pool decks, can significantly benefit from this technology by reducing the risk of cracks and enhancing durability over time, thus ensuring a safer and more stable surface for everyday use.

Benefits of Fiber Mesh Concrete

The intrinsic properties of fiber mesh concrete significantly contribute to the material’s overall strength and durability, setting a new benchmark in construction standards.

By incorporating finely dispersed fibers into the concrete mix, the composite material exhibits a superior resistance to cracking and spalling, attributes directly attributed to its unique composition.

Among the notable advantages are its ability to retain moisture during the curing process, reducing water loss and minimizing the likelihood of shrinkage cracks.

Furthermore, the enhanced impact resistance provided by these fibers aids in absorbing and distributing loads more evenly, thus mitigating the risk of damage under high-stress conditions.

Collectively, these aspects highlight the material’s efficacy in prolonging the lifespan of concrete structures and surfaces, ensuring they remain functional and aesthetically pleasing for years to come.

Strength and durability

Fiber mesh concrete significantly elevates the structural integrity of construction projects by intertwining resilience with malleability, thus creating surfaces that can withstand heavy loads without succumbing to the usual wear and tear. The interwoven fibers serve as a skeleton within the concrete mixture, providing tensile strength that traditional concrete cannot achieve on its own. This unique amalgamation not only prolongs the lifespan of concrete structures but also maintains their visual appeal by preventing surface deformations.

Reduced water loss

One of the standout advantages of fiber mesh concrete is its exceptional capability to curb water loss during the crucial curing period. As the fibers uniformly dispersed throughout the concrete retain moisture more effectively, the risk of shrinkage cracks that typically emerge from rapid drying is significantly minimized. This characteristic not only ensures a more reliable curing process but also contributes to the overall strength and long-term durability of the concrete structure.

Enhanced impact resistance

The inclusion of fiber mesh in concrete slab imparts a notable improvement in handling impact forces, making the material exceptionally suited for environments subjected to heavy loads and mechanical stress. This characteristic is particularly valuable in the construction of commercial floors and industrial applications where the risk of sudden impacts is more prevalent. By evenly distributing stress across the concrete mass, fiber mesh fortifies the structure against potential fractures, safeguarding its integrity and serviceability over an extended period.

Prevention of cracks

One of the most vital benefits provided by fiber mesh concrete is its remarkable ability to prevent the formation of cracks. By evenly dispersing tiny, durable fibers throughout the concrete, this innovative composite material acts to arrest the propagation of micro-cracks that, if left unaddressed, could evolve into larger structural issues. This capacity not only extends the usable life of concrete surfaces but also keeps maintenance costs to a minimum, making it an indispensable solution for modern construction projects.

Comparison between Wire Mesh and Fiber Mesh

The debate between the use of wire mesh and fiber mesh in concrete applications is a pivotal one, underlined by the distinctions in their benefits, limitations, and costs.

This juxtaposition raises important considerations for construction professionals who seek to optimize the robustness, durability, and economic efficiency of their projects.

Exploring these materials’ respective advantages and disadvantages sheds light on their suitability for specific construction scenarios.

Concurrently, evaluating the cost differences is essential for making informed financial decisions without compromising structural integrity.

Such an analysis not only informs the selection process but also anticipates the long-term implications of using either reinforcement method in concrete slabs and structures.

Advantages and disadvantages

The distinction between wire mesh and fiber mesh in concrete applications is marked by a set of advantages and disadvantages tailored to their use. Wire mesh, traditionally used for its robust structural reinforcement, requires manual placement and can be labor-intensive, potentially leading to inconsistencies in dispersion. On the other hand, fiber mesh offers seamless integration into the concrete mix, enhancing tensile strength and resistance to micro-cracking with ease of application, albeit at a possibly higher initial cost.

Cost differences

The difference in costs between wire mesh and fiber mesh for concrete plays a significant role in the decision-making process for construction projects. While wire mesh tends to be less expensive upfront, the labor-intensive installation process can increase overall project costs. Conversely, fiber mesh, while potentially higher in initial material cost, offers savings through reduced labor expenses and efficiency gains in the mixing and application phases, presenting a financially viable long-term investment.

Best Practices for Using Fiber Mesh Concrete

Embracing the innovative strength and durability of fiber mesh concrete in construction projects necessitates a nuanced approach toward its application and handling to maximize its benefits.

Key to this is choosing the appropriate type and dosage of fiber, depending on the specific requirements of the project, which ensures the infused concrete achieves the desired strength and resilience.

Additionally, the process of pouring fiber mesh concrete in cold weather introduces unique challenges that require tailored strategies to prevent premature curing and ensure uniform strength throughout the structure.

Safeguarding against concrete scaling, especially in environments prone to freeze-thaw cycles, is paramount for maintaining the integrity and longevity of the surface.

Addressing these considerations adeptly guides construction professionals in harnessing the full potential of fiber mesh concrete for their projects.

Choosing the right type and dosage

Identifying the optimal fiber type and dosage for a construction project is critical to harnessing the full benefits of fiber mesh concrete. The selection process involves understanding the specific requirements of the project, such as the anticipated load conditions and the environmental factors it will face. Steel fibers, for instance, might be chosen for their high tensile strength in industrial applications, while synthetic fibers could be preferred for their resistance to corrosion in coastal environments. The correct dosage, meanwhile, ensures a balanced distribution of fibers throughout the concrete mix, achieving an ideal composite material that combines flexibility with unparalleled durability.

Tips for pouring in cold weather

Efficient use of fiber mesh concrete during colder temperatures necessitates preventive measures to avoid premature setting and ensure uniform distribution of the fiber mesh within the slab. Keeping the mix water warm, protecting the freshly poured concrete from freezing with insulated blankets, and selecting a fiber mesh suited for lower temperature application are pivotal steps that maintain the concrete’s malleability and structural integrity under challenging weather conditions.

Preventing concrete scaling

Preventing concrete scaling in projects leveraging fiber mesh concrete necessitates meticulous attention to the quality and consistency of the mix to ensure its resilience against freeze-thaw cycles. Opting for a water-to-cement ratio that strikes a balance between workability and strength, while incorporating an air-entraining agent, can significantly reduce the susceptibility to scaling. This approach, when combined with the uniform distribution of fibers throughout the concrete, forms a robust barrier that enhances the surface’s durability against environmental stressors, preserving its integrity over time.

Conclusion

Fiber mesh concrete emerges as an innovation in construction, fundamentally enhancing the strength and durability of concrete structures.

By integrating a variety of fibers such as steel, glass, or synthetic materials into the concrete mix, this advanced composite material demonstrates remarkable resistance to cracking, spalling, and various forms of wear and tear.

It sets new standards in construction by offering improved moisture retention during curing, reducing the likelihood of shrinkage cracks, and distributing loads more evenly, thus significantly prolonging the lifespan of concrete surfaces.

When comparing fiber mesh with traditional wire mesh, the former stands out for its ease of application, though it may present a higher initial cost which is offset by reduced labor expenses and long-term maintenance savings.

For optimal results, choosing the right type and dosage of fiber is critical, as is adapting pouring techniques in cold weather and employing measures to prevent concrete scaling.

Ultimately, fiber mesh concrete represents a step forward in creating resilient, durable, and cost-efficient structures, making it indispensable for modern construction projects.